On the ride home from a job in Devon, my motorcycle’s clutch slips. This is annoying. I am busy and its MOT is soon due.

But “if you can’t change the situation, change your mind”, my friend Fletcher used to say, so I decide to be positive. It’s a chance to learn a new skill. I’ve written ‘clutch’ in a thousand car reviews without ever taking one apart.

Today, that changes.

A garage would want a couple of hours to do this. Owners’ forums say it is relatively simple, except for undoing one big nut, for which I’ll need an impact driver. I have one. So I give myself a day to do it.

First I need to remove the bash plate, which being aluminium is simple, and the exhaust, which containing 24-year-old iron is not.

I immediately shear two bolts and disintegrate a bracket around a crumbling intersection. Regardless of my mindset, this is definitely annoying.

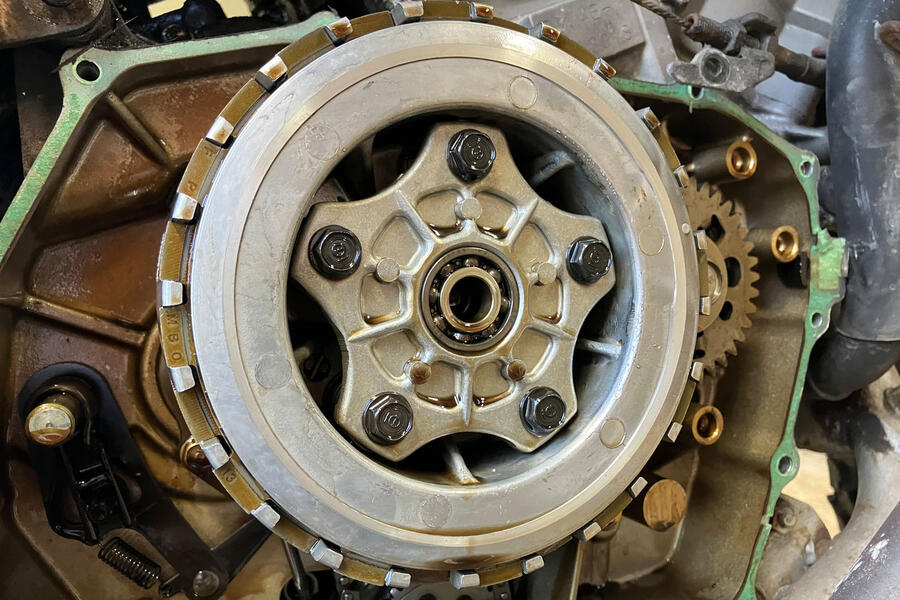

The clutch cover is removed easily and I find what’s meant to be the hard bit: the nut.

This is ‘staked’: part of a flange around the nut is bashed into a notch on the shaft. It’s a crude and rudimentary method of preventing it working loose but, given it hasn’t budged in 75,000 miles, clearly works.

I’m told to prise out the stake with a screwdriver but can’t. I could chisel it off, I’m told, or grind it, but either may leave metal shards in the engine.

Simply, the impact driver may do the job, I read. But my battery-powered one isn’t up to it.

I once vowed that if I didn’t have the right tool for a job, I would either buy it or get a mechanic to do the work instead. The bike is already in pieces, so I go shopping. The day passes.

I like my new air impact driver, which arrives a day or two later. The thread on the bottom looks big, though, and my UK-spec air hose connectors won’t quite fit its American-spec threads.

I’m sure I or a nearby shop have something to convert one to the other. I don’t. The shops don’t. So I go online.

A few days pass. Then everything connects. Within three seconds the nut is undone. Per hour of operation, the air gun is currently costing £180,000.

Join the debate

Add your comment

Man, I feel your pain — those old exhaust bolts are always the worst part. It's like the job tries to break your spirit before you even get to the ragdoll hit real task. That staked nut sounds like a proper headache too; I’ve had luck in the past using a punch and hammer to carefully "walk" the stake out enough to get a bite with the driver, but yeah, a low-torque impact won’t cut it. Maybe try borrowing or renting a corded one with more muscle? You’re definitely close though — hang in there!

Couple of points, you never know what's possible till you try, I managed to replace a KTM clutch in 1 hour. I'd also be amazed Honda don't sell a locking tool. Why not make the story complete by stateing how much a Honda dealer charge, plus what they'd charge to fix that exhaust.

Bit weird you've an air compressor but no impact driver, they're really not that expensive. You may well of saved yourself some money plus have another tool.