An American technology company claims to have developed a new type of electric car battery that can add up to 50% more range without any increase in size.

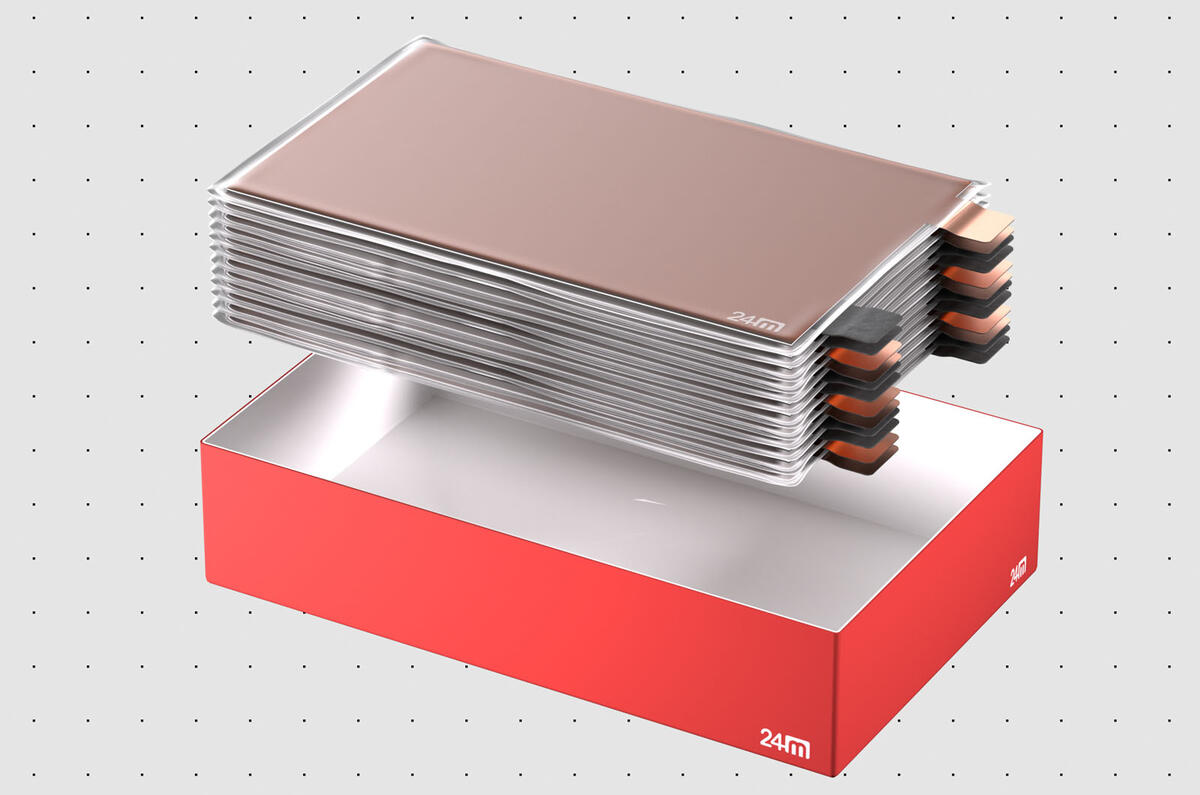

Massachusetts-based 24M Technologies has detailed a new electrode-to-pack (ETOP) arrangement, which it claims offers "unmatched energy density", by sealing each electrode in a thin polymer film that is then integrated directly into the pack.

This new approach does away with the conventional method of constructing modules and packs from individual cells, which 24M said means the average lithium ion battery "features a large proportion of inactive, non-energy-carrying materials" - such as the metals and plastics used in the structure of the battery itself.

By eliminating all these supporting structures, 24M said manufacturers will be able to "achieve the highest energy density" possible.

And it's not exclusive to any one chemistry: the company claims ETOP can be used in NMC, LFP, NCA and sodium batteries, as well as more traditional lithium ion packs.

Ultimately, ETOP allows a claimed 80% of a battery's volume to be made up of electrodes, compared with what 24M said is "the 30% to 60% of traditional battery packs".

As a result, a given battery can be dramatically increased in capacity but occupy the same physical space - and another result of the material savings, 24M claims, is that an ETOP battery is also cheaper to build.

It also offers more flexibility in terms of the actual shape of the battery, with the polymer cells being more physically malleable - facilitating "virtually any shape" that suits the application and the space available.

24M said the technology is on the cusp of production-readiness, with the first prototypes now complete and undergoing evaluation, and is "ready for manufacturers to incorporate it quickly and cost-effectively into existing processes".

Crucially, 24M said the relative similarity of its technology to today's conventional battery structures means that it would require only "modest capex investments" for vehicle manufacturers to start using ETOP batteries.

It acknowledged that the cost of building an ETOP-compatible production line requires "some relatively modest investment" but said the method is ultimately "significantly less expensive than traditional cell-to-pack approaches".

That's because ETOP does away with "unnecessary materials associated with making individual cells", as is the current convention, including "potentially hundreds of cans, busbars and the like".

Asked why ETOP batteries weren't already commercially available, given the claimed increases in flexibility and cost-savings, the company said: "24M ETOP is a new innovation and, as with anything related to automotive production, it takes time to make its way into the market.

"We are encouraged by the strong OEM interest and look forward to delivering first prototypes this fall. This new and novel approach to battery design is patented and only available from 24M, so you will not see it from anyone else."

The company told Autocar that one unnamed "prominent OEM" will take delivery of prototypes for its own testing in the coming months, and it's working with several others on development and evaluation with a view to getting the technology into public hands in just a couple of years.

Join the debate

Add your comment

after 28 - so 29, hence ready for production means might be in a car in 4 years time. Having said that of course i hope it all goes well.

This sounds like the typical too-good-to-be-true article that precedes an appeal for further investment. But if the company can deliver on its promise that the market can afford, then jolly good luck to it...