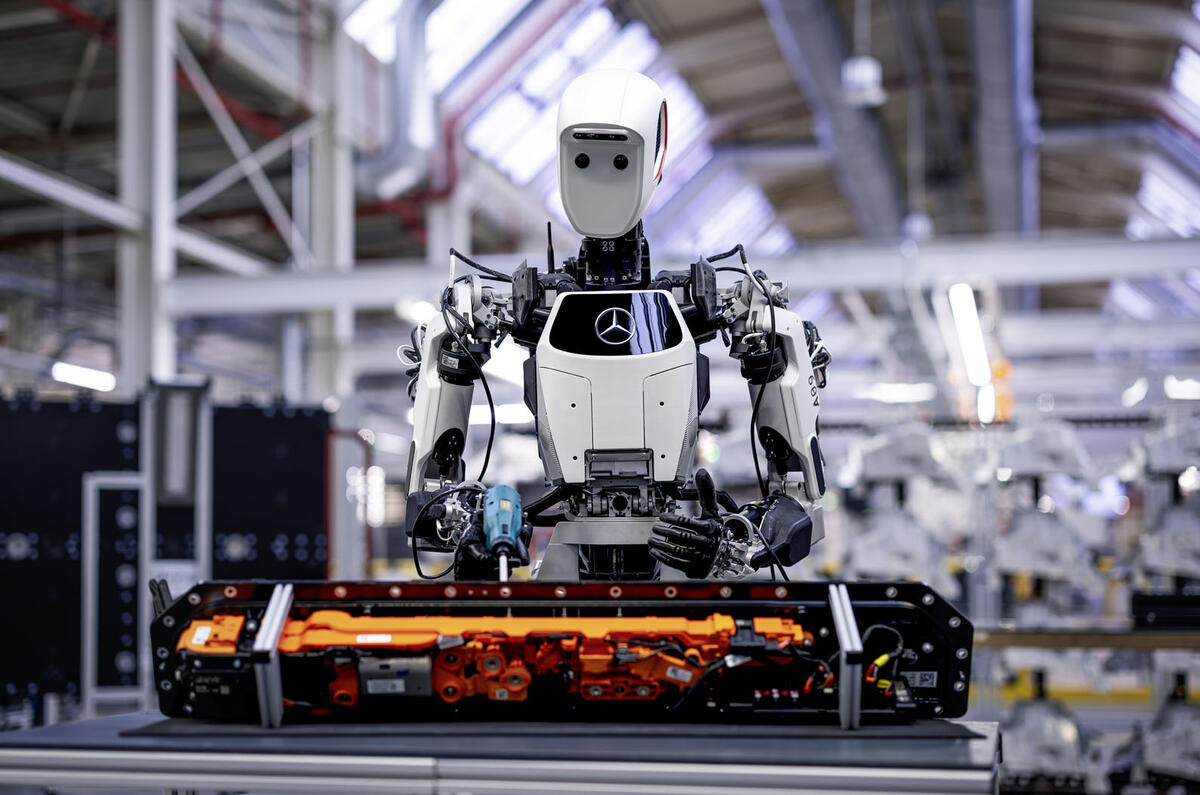

Mercedes-Benz is planning the roll-out of humanoid robots and new artificial intelligence (AI) software across its US and European manufacturing lines to streamline processes, increase efficiency and save money.

The Apollo robots from American company Apptronik and AI software from Google DeepMind are currently being tested at the car maker’s Digital Factory Campus at its factory in Berlin, Germany.

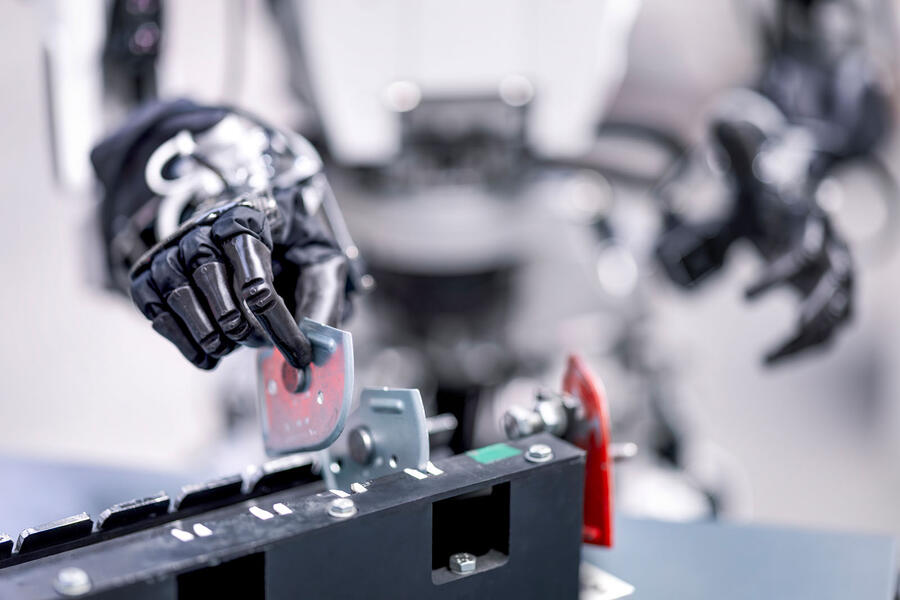

Apollo, a bipedal humanoid robot designed to mimic human actions, is being tested for logistics tasks, such as transporting components and assisting workers on the production line.

Unlike traditional industrial robots, which are fixed in place and perform repetitive tasks, Apollo is capable of navigating factory floors and handling a variety of different, non-repetitive functions, speeding up manufacturing processes.

Mercedes is initially deploying the robot in intra-logistics, moving materials between workstations to support human workers.

It has also confirmed an investment of more than £85 million in Apptronik, signalling a deeper partnership that is expected to expand into other areas of manufacturing automation.

Jörg Burzer, Mercedes' director of production, quality and supply chain management, told Autocar: “We’re training tasks away from the workforce. We’re thinking hard about how we’re going to implement it. It’s important to choose the right tasks: repetitive and hazardous.”

The investment in Apptronik, which has worked closely with NASA since its founding in 2016, allows Mercedes to leverage the company’s recently announced partnership with Google and its DeepMind technology.

This includes two new AI models: Gemini Robotics and Gemini Robotics Extended Reasoning. Both models run on Gemini 2.0, which Google describes as its most capable AI model to date, going beyond text and image output into physical action and commands to control robots.

The AI-enhanced automation processes are being deployed in Mercedes' quality control and production monitoring, where assistants can analyse production anomalies, detect defects and optimise workflows.

“AI takes over the tasks we enjoy less, giving us time to focus on value-adding activities. It’s a huge efficiency gain,” said Burzer.

Together with these robotic advancements, Mercedes has also updated its digital production system with new AI-driven software tools, including a revised Chatbot Ecosystem.

Join the debate

Add your comment

Don't worry, Peter... the robots will have eaten us all by then.

More automation,less humans in Factories. Building cars, what are we going to do with people when there's no jobs that AI robot can do better, faster than a human?