Alfa Romeo CEO Jean-Philippe Imparato was on fighting form when we met him at the new facility that’s ramping up to full-scale production of the Tonale crossover. “It’s world- class everything: a premium plant for premium products,” he pithily summarised.

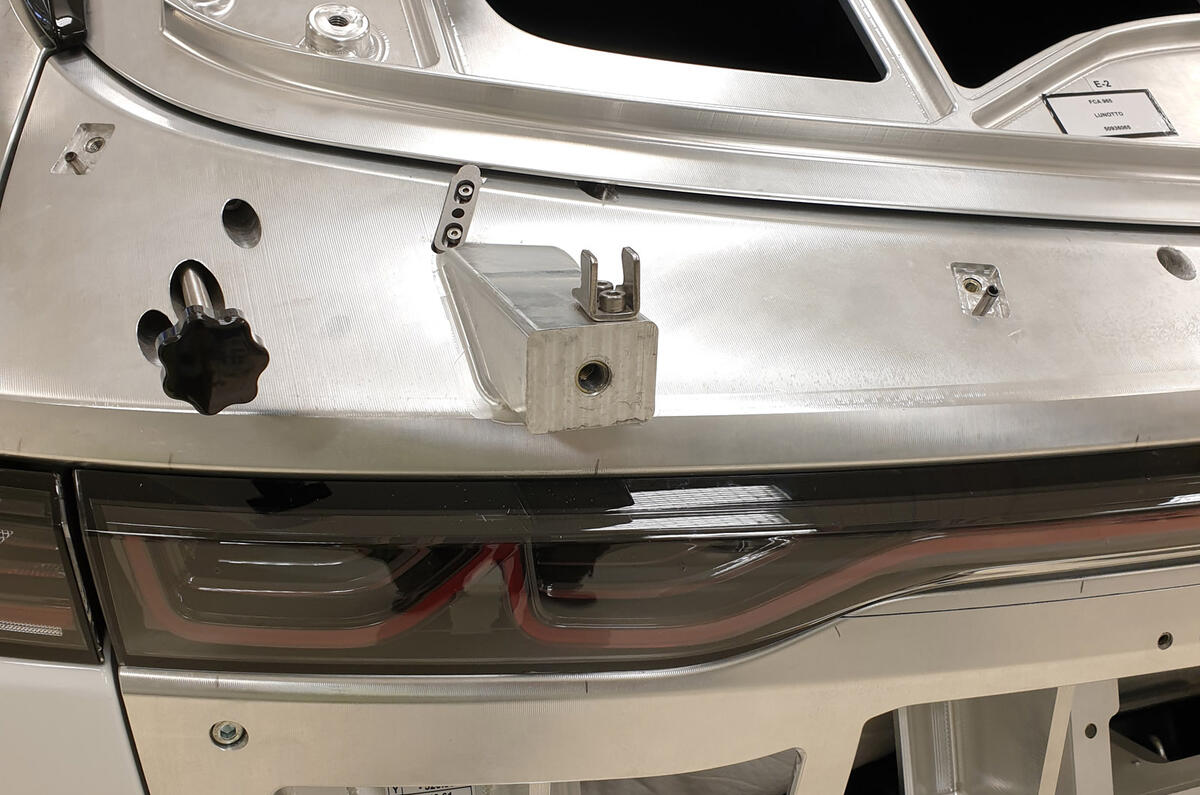

Imparato was extremely keen to deliver his message that the recently unveiled Alfa Romeo Tonale is unlike any past Alfa Romeo, thanks to hitherto unseen levels of deeply rooted quality and precision assembly.

Join the debate

Add your comment

Alfa Romeo management intends to improve quality for the first time in a century.

Salutiamo Jean-Philip, l'imperatore