One of the motorsport sector’s proudest boasts is that it discovers and develops technologies that bring vital and rapid benefits to wider society.

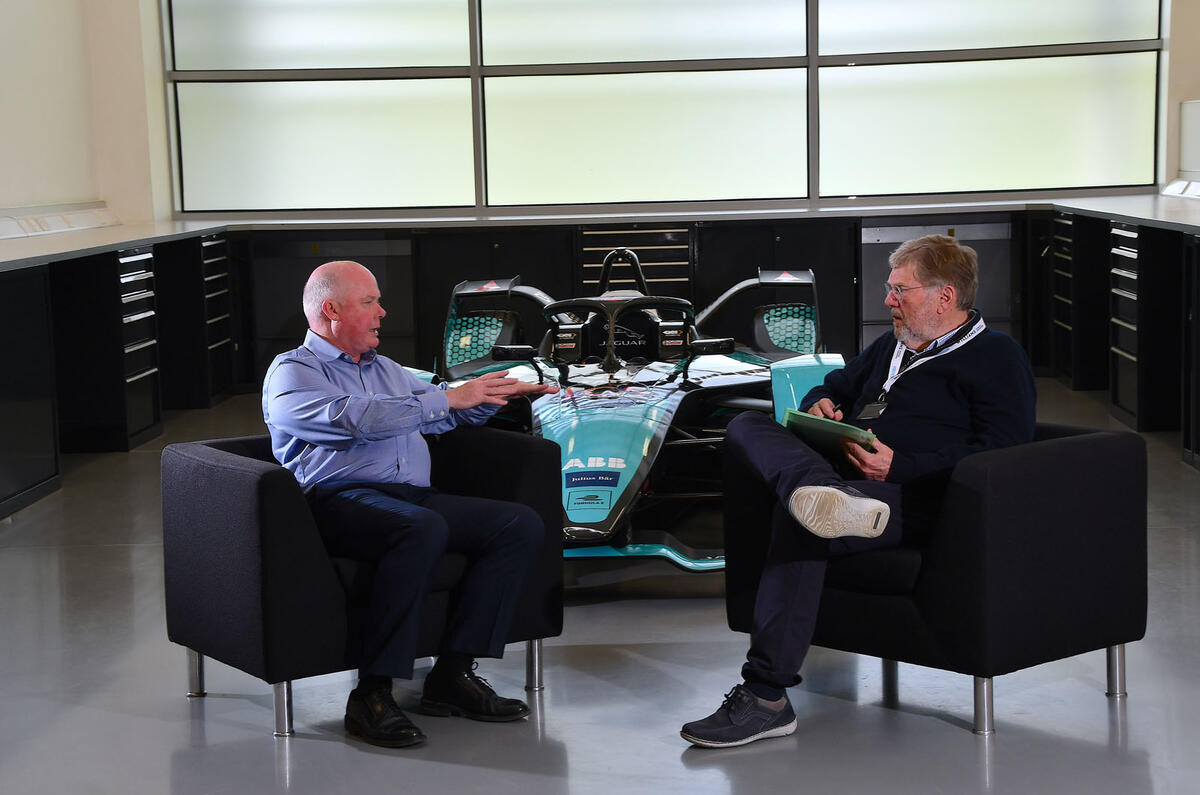

The latest to enter this hallowed space is Williams Advanced Engineering (WAE), the Oxfordshire company that was spun out of the Williams Formula 1 team back in 2010.

Add your comment