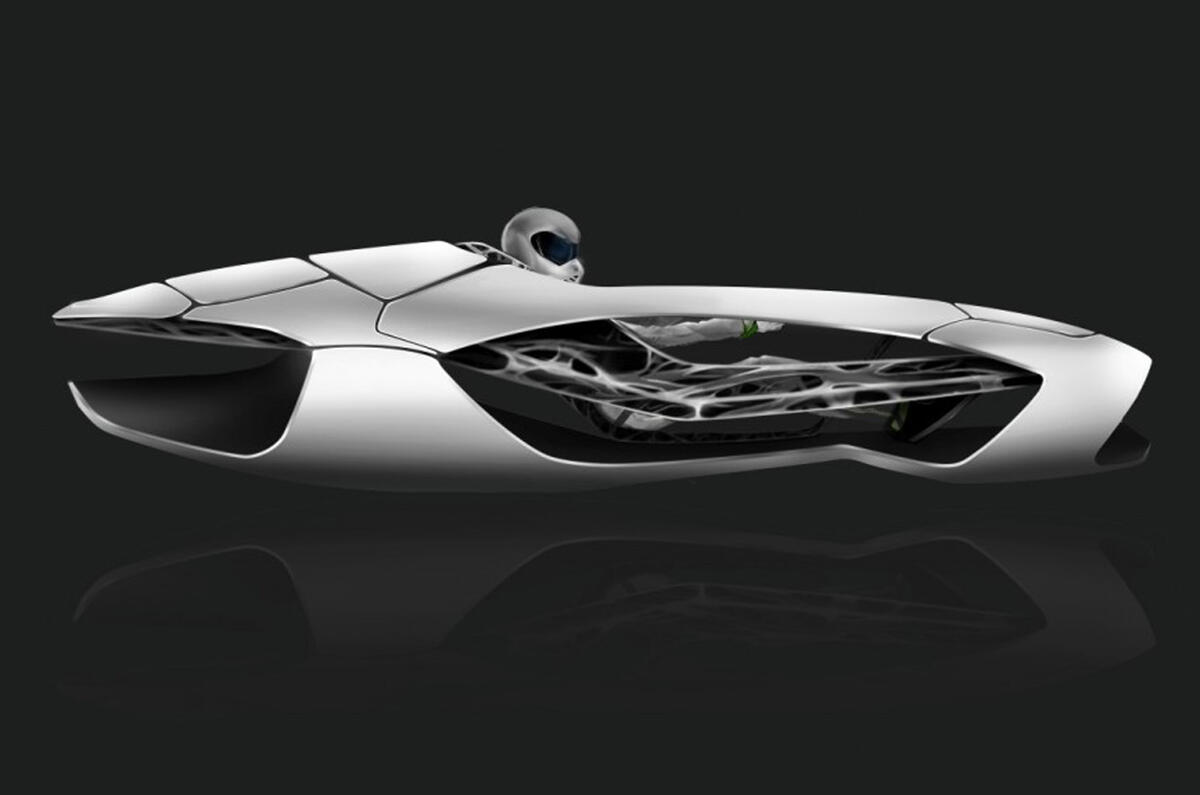

The futuristic Edag Genesis has been revealed at the Geneva motor show. It's a concept car that lives up to its ‘car of the future’ billing and that demonstrates the potential of production techniques that could allow a one-piece car body to be built in a single process – potentially granting huge cost savings.

Edag, an engineering service provider in the automotive industry, is a specialist in industrial application of manufacturing processes.

Genesis has been produced to demonstrate a body structure made using a process called additive manufacturing. The Genesis is modelled on what Edag describes as "the bionic patterns of a turtle, for which it has a shell that provides both protection and cushioning, much like when it's part of the animal's bony structure".

The structure could not be made by conventional tools, says Edag, but only by new techniques. The company investigated processes including selective laser sintering (SLS), selective laser melting (SLM), stereolithography (SLA), and fused-deposition modelling (FDM), before settling on a modified version of the latter technique.

Edag says FDM makes it possible for components of almost any size to be produced, as there are no pre-determined space requirements. Instead, the structures are built up layer by layer by robots applying thermoplastic materials.

The robots can also apply carbonfibre during the production process to achieve the required strength and stiffness properties.

Join the debate

Add your comment

Interesting tech

I like it, but....

This looks more like concept art for the new Star Wars film!