Many moons ago, Steve Sutcliffe, erstwhile editor of this magazine, had a go in Nick Mason’s McLaren F1 GTR, aka chassis #10R.

It was 2009, and the subsequent YouTube video (1.2 million views and counting) remains one of the best there is for conveying the violence that separates proper racing cars made road-legal from the comparatively tame track-day toys that big OEMs spin from polite mainline models.

There’s a moment three minutes in when the acid response of the Mac’s 6.1-litre V12 to Steve’s gratuitous downshifting via the car’s sequential ’box would be frightening were it not so glorious.

I mention this only because a blue coupé with a sardonic grin, and whose yoke I’m now tucked behind, is giving off a similar vibe to the F1 in Sutters’ ear-popping video. It’s not quite on the Mac’s level but is still unforgettably feral.

Not far from Leeds is the HQ for Ginetta Cars, the company that produces this pint-sized road racer, also dubbed ‘GTR’. Its wildness makes sense when you consider that Ginetta is first and foremost a motorsport specialist.

Over the years its cars have afforded plenty of rising talent a vital first taste of real racing. This includes F1 star Lando Norris, who still raves about his 100bhp but oh-so sweet-handling G40 Junior.

At the other end of Ginetta’s broad motorsport capability is the extraterrestrial G60-LT-P1 – a homegrown, top-tier prototype built to take on Toyota at Le Mans at the tail end of the LMP1 era.

The G60 really did have the aerodynamic package to display some giant-slaying performance, as demonstrated by its pace through Porsche Curves. Alas, the V6 wasn’t potent enough elsewhere. Today the G60 sits in the atrium at Ginetta’s HQ, next to a tiny 1965 G10 roadster. As bookends to the company’s historical output, they are a striking pair.

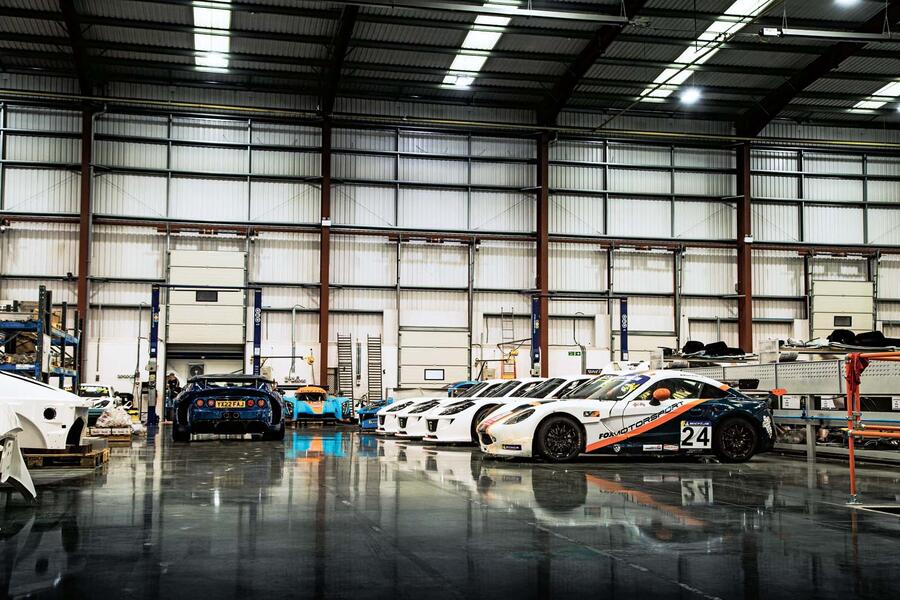

The really remarkable bit about Ginetta’s business is something you can appreciate only from the hubbub of the factory floor: it is how self-sufficient – vertically integrated – the production process is.

Explore the place and you will see it all: steel spaceframes being welded for the G40 and G56 racers; the huge autoclave (the ‘tea urn’) that bakes composite panels for the LMP3 prototypes; water pumps being machined; engines assembled and benched; gearboxes stripped and rebuilt; wishbones fabricated; wiring looms painstakingly knitted; and billet aluminium everywhere.

Join the debate

Add your comment

I've never see a Ginetta road car on the road, maybe they are more common in other parts of Blighty?